钢材的酸洗处理广泛地应用于冷轧板材坯料即热轧板材的表面氧化铁皮的去除,如热轧型钢需进行磷化或镀层等表面处理加工前去除氧化铁皮;焊接管材在镀锌或进行其它热浸镀、电镀加工前的表面预处理;退火处理后的钢材如管材、型材、线材等冷拔加工前的表面处理;钢铁加工件进行电镀、电刷镀前的除锈处理以及不锈钢和特殊钢生产过程中的类似处理。目前酸洗仍是钢铁生产和钢铁表面处理时不可或缺的工艺过程。但是,钢材酸洗处理工艺的采用也带来如下的一些问题:

(1)大量消耗钢铁材料和酸

在酸洗的过程中,有的主要通过酸与铁皮的化学反应,溶解相应的金属氧化物的溶解作用来除去铁皮。有的,如使用硫酸进行钢材酸洗时,还要借助于酸与钢铁发生化学反应产生的氢气泡的剥离作用来除去氧化铁皮。因此在酸洗过程中,大量消耗酸是必然的。虽然在酸洗中使用酸洗缓蚀剂可以降低钢铁的金属消耗,但是仍有相当量的金属铁损失掉。

(2)可能降低钢材的物理性能

在酸洗过程中,金属铁和酸之间发生化学反应并产生氢气。由于酸洗液中的氢的化学位高于被酸洗的钢材中氢的化学位,生成的氢会渗入钢中并积存起来造成 氢脆,从而影响钢材的机械性能或以后的加工处理。

(3)会带来一系列的环境污染问题

采用酸洗工艺对钢材或零件进行表面处理,由于钢材的品种、产品的规格和生产的规模各不相同,从而造成了在生产装备和生产环境方面有着很大差别。如酸洗槽体的密封、对生产设备的腐蚀、酸洗车间的通风排风、酸雾的排出和处理以及污水的处理和排放等方面,处理方法和处理水平相差悬殊。从而会带来许多环境保护方面的问题,而需要一一加以处理和解决。

(4)废酸和铁盐的处理问题

钢铁的酸洗在消耗大量金属铁的同时还产生大量的废酸液与相应的酸和氧化铁或生成的铁盐溶液。为了回收和利用这些废酸液和铁盐,需要较大的投资来建设相应的回收和处理设备。特别是对于一些小型的、小批量的钢铁件进行酸洗处理时,往往会出现酸洗废液难以集中进行处理的情况,一旦发生直接排放的情况,就会对对环境造成严重污染。

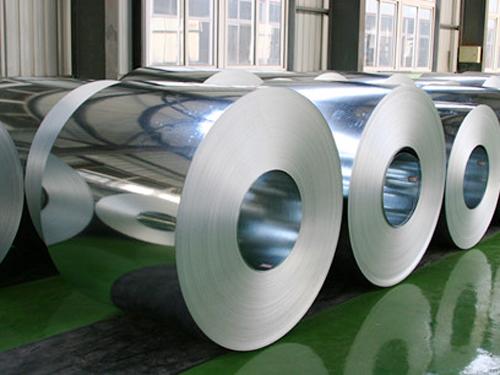

Pickled strip / galvanized strip / Tangshan pickled strip

The pickling treatment of steel is widely used in the removal of oxide scale on the surface of cold-rolled plate blank, i.e. hot-rolled plate. For example, the oxide scale should be removed before the surface treatment of hot-rolled section steel, such as phosphating or plating; the surface pretreatment of welded pipe before galvanizing or other hot-dip galvanizing or electroplating; the surface treatment of annealed steel before cold drawing, such as pipe, profile, wire, etc Surface treatment; rust removal before electroplating and brush plating for iron and steel workpieces, and similar treatment in the production process of stainless steel and special steel. At present, pickling is still an indispensable process in steel production and steel surface treatment. However, the adoption of steel pickling process also brings some problems as follows:

(1) Large consumption of steel materials and acids

In the process of pickling, some iron sheets are removed mainly through the chemical reaction of acid and iron sheet, and the dissolution of corresponding metal oxides. Some, such as the use of sulfuric acid for steel pickling, but also with the help of acid and steel chemical reaction of hydrogen bubble stripping effect to remove iron oxide scale. Therefore, it is necessary to consume a lot of acid in the pickling process. Although the use of pickling inhibitor in pickling can reduce the metal consumption of steel, there are still a considerable amount of metal loss.

(2) May reduce the physical properties of steel

In the process of acid pickling, there is a chemical reaction between iron and acid and hydrogen is produced. Because the chemical position of hydrogen in acid washing solution is higher than that in acid pickling steel, the generated hydrogen will penetrate into steel and accumulate to cause hydrogen embrittlement, which will affect the mechanical properties of steel or subsequent processing.

(3) It will bring a series of environmental pollution problems

The surface treatment of steel or parts by pickling process is very different in production equipment and production environment due to different varieties of steel, product specifications and production scale. For example, the sealing of pickling tank, the corrosion of production equipment, the ventilation and exhaust of pickling workshop, the discharge and treatment of acid mist, and the treatment and discharge of sewage, the treatment methods and treatment levels are quite different. It will bring many environmental protection problems, which need to be dealt with and solved one by one.

(4) Treatment of waste acid and iron salt

The pickling of iron and steel consumes a lot of metal iron, at the same time, it also produces a lot of waste acid liquid, corresponding acid and iron oxide or generated iron salt solution. In order to recover and utilize the waste acid and iron salt, it needs a large investment to build the corresponding recovery and treatment equipment. Especially for some small and small batches of steel parts, it is often difficult to treat the acid pickling waste liquid in a centralized way. Once it is discharged directly, it will cause serious pollution to the environment.